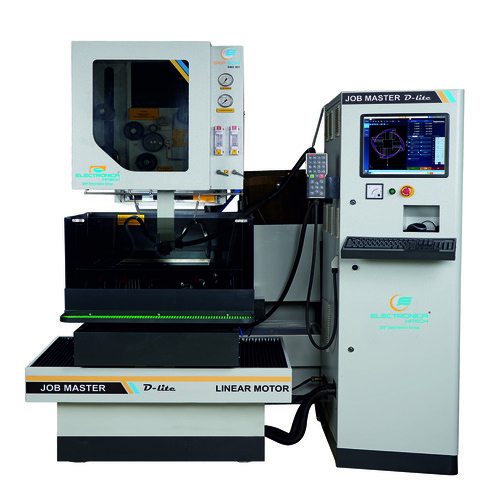

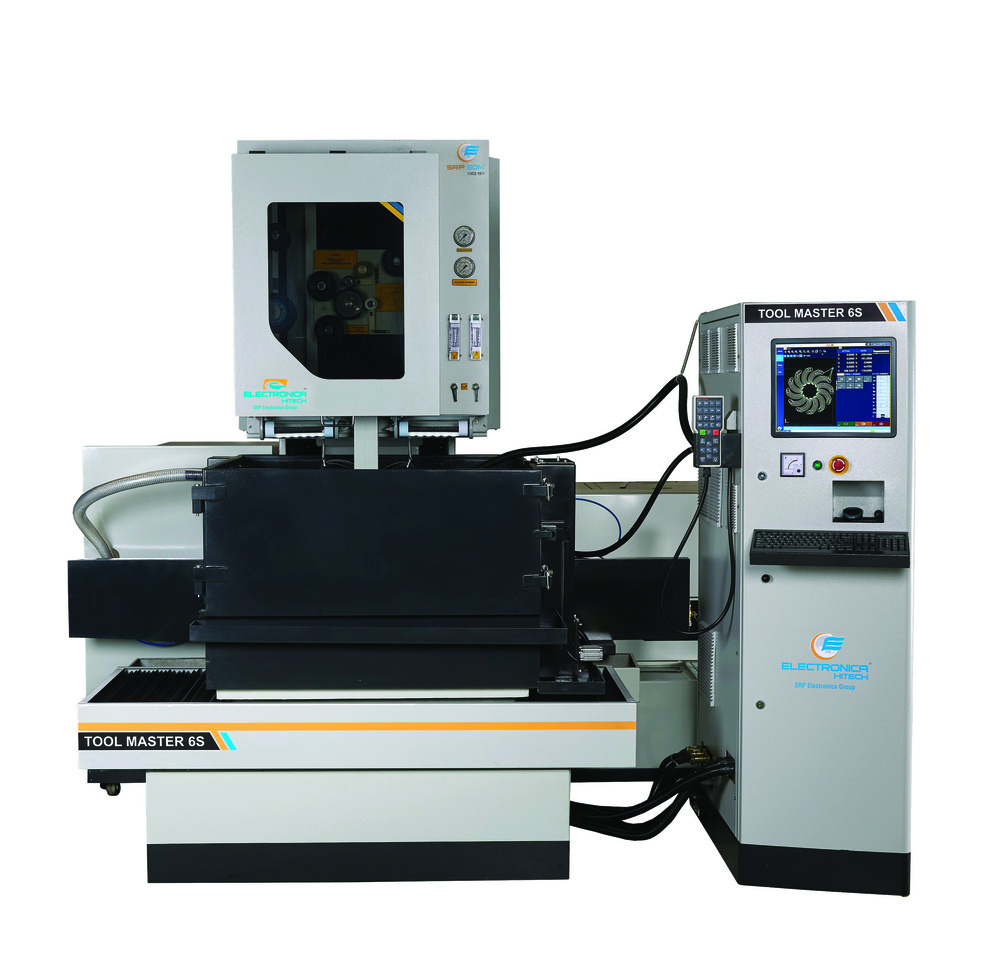

CNC Wire Cut EDM Machine

CNC Wire Cut EDM Machine Specification

- Product Type

- CNC Wire Cut EDM Machine

- Power Source

- Electricity

- Operating Type

- Automatic

- Dimension (L*W*H)

- 635 x 475 Millimeter (mm)

- Weight (kg)

- 300 Kilograms (kg)

- Color

- White

- Usage & Applications

- Industrial

CNC Wire Cut EDM Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- All India

About CNC Wire Cut EDM Machine

We have been serving our respected clients since 1995 by manufacturing and supplying excellent-grade CNC Wire Cut EDM Machine. It is widely used in industries to produce precision parts for different applications. Common industries where this machine is utilized are aerospace, medical, defense, automotive, electric/semiconductor manufacturing industries, and many more. It uses rapid and recurring electric arcing discharges between an electrode and workpiece. Offered CNC Wire Cut EDM Machine is highly appreciated by our clients for its capability to form complex geometry, easy cutting of hard materials, and cost-effectiveness. We check these machines on various quality parameters prior to dispatch to our clients.

Features

- Compact rigid T base Structure

- Japanese AC servo drive for all 5 axes

- Direct Coupling for AC Sercvo motors

- C 3 grade Japanese Ball screws

- Table Moving Structure

- Compact footprint

- Front loading Machine

- High Precision LM guide ways

CNC Wire EDM

Specifications:

- X/Y Travel: 400 x 300 mm

- U/V Travel: 80 X 80 mm

- Z Travel: 250mm

- Max. Work piece weight 300 Kg

- Worktable Size ( L XW) : 630 X 470 mm

The automatic CNC Wire Cut EDM Machine streamlines complex metal shaping processes, reducing manual intervention and improving consistent outcomes. Its reliable electric power source ensures operational stability, catering to diverse industrial sectors. With precise engineering and intuitive controls, businesses can elevate their manufacturing capabilities and maintain productivity with minimal downtime.

Compact Design for Industrial Versatility

Despite its substantial 300 kg build, the machine has a compact footprint, making it suitable for various factory layouts. The 635 x 475 mm dimensions facilitate space optimization, allowing seamless integration into production lines. Its sturdy construction and durable finish further contribute to its enduring performance in demanding operational settings.

FAQs of CNC Wire Cut EDM Machine:

Q: How does the CNC Wire Cut EDM Machine operate automatically in industrial settings?

A: This machine utilizes computer numerical control (CNC) technology to automate the wire cut electrical discharge machining process. Operators program the desired cutting parameters, and the equipment manages the precision cutting tasks automatically, ensuring consistent, high-accuracy results without manual intervention.Q: What materials can be processed using this CNC Wire Cut EDM Machine?

A: The machine is designed for cutting and shaping metal workpieces, including tool steels, alloys, and conductive materials commonly used in industrial manufacturing. Its advanced EDM process is suitable for intricate and hard-to-cut components.Q: When is it beneficial to use a CNC Wire Cut EDM Machine over conventional methods?

A: This machine is preferable when high precision and complex geometries are required, such as in mold making, aerospace parts, and intricate tooling. Its automatic operation reduces labor costs and increases productivity, making it advantageous for high-volume or specialized tasks.Q: Where can businesses in India obtain manufacturer support and service for this machine?

A: Indian businesses can acquire this machine from authorized manufacturers, service providers, and suppliers based across India. Comprehensive support is available, including installation, maintenance, and training services tailored to various industrial requirements.Q: What is the process involved in wire cut EDM machining with this model?

A: The process involves passing an electrical current through a thin wire to precisely erode material from the workpiece, following programmed paths. This method ensures minimal mechanical stress and allows accurate cuts for complex and delicate components.Q: How can users optimize the machines performance and ensure longevity?

A: Users should follow recommended maintenance routines, keep the machine clean, and regularly check electrical and mechanical components. Proper programming and using quality materials also help maintain peak performance and extend the machines service life.Q: What benefits does the automatic feature offer over manually operated EDM machines?

A: The automatic operating type minimizes human error, improves reproducibility, and significantly reduces processing time. It also allows for continuous operation and better resource allocation, enhancing industrial efficiency and overall output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EDM Machines Category

ZNC EDM Machine

Price Range 700000.00 - 1200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Color : White

Machine Type : ZNC EDM

Usage & Applications : Mould & Die Making, Component Machining

|

ELECTRONICA HITECH MACHINE TOOLS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry