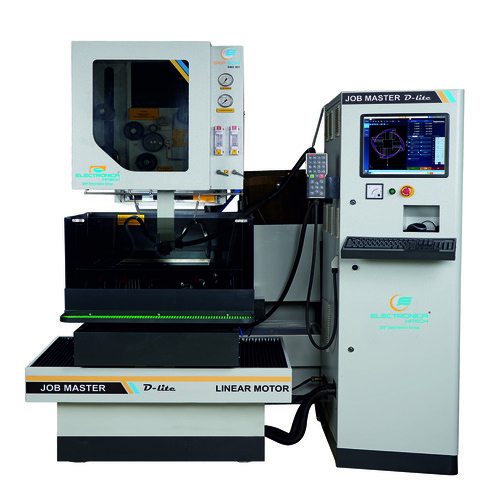

ZNC EDM Machine

ZNC EDM Machine Specification

- Power Rating

- 3 Phase, 380V/50Hz

- Model No

- ZNC-EDM-400

- Machine Type

- ZNC EDM

- Cooling System

- Integrated Oil Cooling

- Accuracy

- 0.01 mm

- Voltage

- 380V Watt (w)

- Noise Level

- Low

- Lubricating System

- Automatic Central Lubrication

- Production Capacity

- Multiple Shifts Continuous

- Features

- Manual & Z-Axis Programmable, Anti-Carbon Buildup Circuit, Easy Operation

- Frequency

- 50/60 Hz

- Frame Type

- Rigid Cast Iron

- Operating Temperature

- 5C to 40C

- Motor Power

- 0.75 kW (Servo/Stepper Drive)

- Connectivity Options

- USB Port, RS232C (Optional)

- Drive

- Servo/ZNC Pulse Drive

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Automatic

- Power

- 3.0 kVA

- Pressure

- Standard Shop Air Pressure

- Surface Treatment

- Other

- Dimension (L*W*H)

- 1100mm x 950mm x 1800mm Millimeter (mm)

- Weight (kg)

- 1250~2000 Kilograms (kg)

- Color

- White

- Usage & Applications

- Mould & Die Making, Component Machining

- Screen Display

- Digital LED/LCD

- Optional Accessories

- Automatic Fire Suppression, Graphite Tooling

- Programmable Functions

- Multi-step Machining, Pause/Resume

- Table Size

- 600mm x 400mm

- Work Tank Size

- 900mm x 600mm x 350mm

- Max Machining Current

- 50A

- Max Electrode Weight

- 50 kg

- Dielectric Fluid

- EDM Oil

- Max Workpiece Weight

- 800 kg

- Safety Features

- Overload & Overheat Protection, Emergency Stop

ZNC EDM Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About ZNC EDM Machine

We are known to be a reputed entity of the industry by manufacturing and exporting the best quality ZNC EDM Machine. Using optimum-class factory material with the use of sophisticated tools and techniques, this machine is manufactured at our well equipped unit. Made available in numerous specifications, these sturdily constructed and high functionality machines are widely applauded for their excellent strength and high load capacity. We offer this ZNC EDM Machine at affordable price.

Features:

- Efficient performance

- Longer functional life

- Operational fluency

ZNC EDM Machine Highlight:

- TFT LCD Colour Display

- Single Screen Menu

- ISO- Bipulse technology

- Micro Controller based antiarc control

- LM guideways

- Ball Screw for X, Y axes

- Double Door Tank

- DC Servo System for Z axis

Product details

|

Display |

19 high resolution wide screen LCD |

|

Features |

AC Servo System for Z axis |

|

Country of Origin |

Made in India |

|

Max Load Of Table |

300 -500 Kg |

|

Weight |

1250-2000 KG |

|

Brand |

Electronica |

|

Model Name/Number |

ELTECH D300 ZNC/ D400 ZNC |

Experience unparalleled machining precision with the ZNC EDM Machines digital control interface. Its multi-step programming, real-time pause/resume, and easy-to-navigate digital LED/LCD display streamline complex EDM processes, maximizing accuracy and productivity.

Superior Build and Robust Safety

Crafted with a rigid cast iron frame and powder-coated surface, the machine is built for stability and durability under heavy loads. Comprehensive safety featuressuch as overload and overheat protection, emergency stop, and optional automatic fire suppressionsafeguard both operators and equipment during operation.

Versatile Applications and Seamless Operation

Designed for continuous operation across multiple shifts, the ZNC EDM Machines powerful 3-phase, 380V/50Hz system ensures exceptional performance in mould and die making, as well as precise component machining. Its integrated oil cooling, automatic lubrication, and low-noise profile enhance usability and maintenance.

FAQs of ZNC EDM Machine:

Q: How does the ZNC EDM Machine ensure precision during machining operations?

A: The ZNC EDM Machine utilizes advanced ZNC digital control and programmable functions, enabling precision through features like multi-step machining and 0.01 mm accuracy, ensuring consistent and detailed results on complex workpieces.Q: What safety features are included with the ZNC EDM Machine?

A: This EDM machine is equipped with overload and overheat protection, an emergency stop button, and offers optional automatic fire suppression, all designed to protect both the user and equipment during continuous production processes.Q: When should I use the automatic pause/resume feature?

A: The automatic pause/resume function is ideal when you need to inspect the workpiece, change electrodes, or adjust parameters without restarting the entire process, thus saving time and maintaining machining accuracy.Q: Where can the ZNC EDM Machine be installed for optimal performance?

A: The machine should be installed in a clean, temperature-controlled environment (5C to 40C) with standard shop air pressure, stable 3-phase electrical supply (380V), and ample space for its 1100mm x 950mm x 1800mm dimensions.Q: What is the process for connecting external devices to the machine?

A: The ZNC EDM Machine supports USB and optional RS232C connectivity, allowing you to import machining programs and export data conveniently for improved workflow integration and data management.Q: How is maintenance managed for this EDM machine?

A: The machine features integrated oil cooling and an automatic central lubrication system, which reduce routine maintenance and enhance machine longevity. Regular checks of dielectric oil and safety mechanisms are recommended for optimal performance.Q: What are the main benefits of using this machine for mould & die making or component machining?

A: Employing the ZNC EDM Machine increases productivity through continuous multi-shift operation, precision digital control, robust safety systems, and user-friendly programming, making it highly effective for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EDM Machines Category

CNC Wire Cut EDM Machine

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Operating Type : Automatic

Product Type : Other, CNC Wire Cut EDM Machine

Usage & Applications : Industrial

Color : White

|

ELECTRONICA HITECH MACHINE TOOLS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry